I`ll admit it - this is both the most common question we get, and probably the most frustrating one. Frustrating since it is impossible to answer without two pieces of info we seldom get, and probably just as frustrating for the person asking. Let`s see if we can straighten this out once and for all.

|

| Great tools - but how can you ensure they get what they need? |

Wiring

In order to know what size wiring to use, you need to know two things:- The maximum load/ draw - typically found in the manual.

- The total length of wiring from the battery to the unit - you have to measure.

Without that information, we are left guessing. The consequence of using undersized (to thin) wiring is voltage drop and potential heating of the wiring. This again leads to other issues, typically called "bugs", where your marine electronics does not work the way you want it to.

In order to find the maximum draw, you must check the manual. If you can`t find it in the manual, ask the dealer or manufacturer. Here are a few examples from manuals of popular marine electronics so you know what you are looking for:

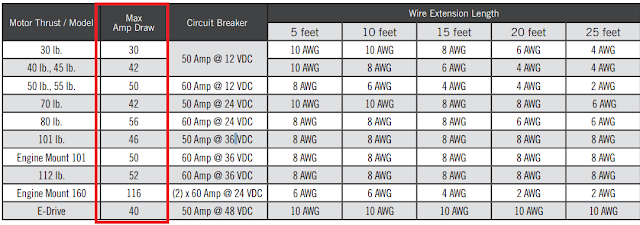

Minn Kota Ulterra (easy to find - good work there MK)

|

| 30 to 116 amps depending on model. |

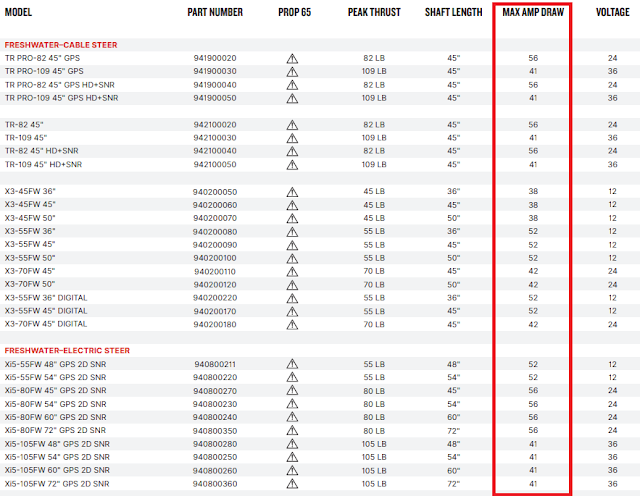

Motorguide Xi5 (hard to find - what are you thinking MG?)

|

| 41 to 56 amps depending on model |

Lowrance HDS Live (easy to find - good work there Lowrance)

|

| 2,4 to 4,9 amps depending on model. |

Garmin Echomap Plus 92sv (easy to find - good work there Garmin)

|

| 1,5 amps |

Now you know how to find the maximum draw, then we need to know the total length of wiring. However, before we look at that, let us look at WHY it is important to know both the maximum draw and the total length of wiring:

Voltage drop means that there will be less power (A) getting to your unit then what is leaving the battery, typically leading to problems with the unit not working as it should. Voltage (V) tells you something about how much power (A) can potentially be delivered, so if the voltage drops, power most likely drops as well.

Heat is the result of the voltage drop. As you might remember from school, energy never disappears, it only transforms into another type of energy. Thin cables and high load leads to the wires heating up, as the resistance in the wiring is hindering the load to "flow" through. Kind of like trying to push a thick leader through a tiny loop on your jerkbait. The leader and the loop has to match, or the loop has to be larger than the leader, or your leader will not go through as it should. Electric current need enough "space" in the wires to pass through without resisstance. (In electrical terms, that resistance is called Ohm).

|

| Ohm is a bi... (photo; https://www.smartautotraining.com/) |

The length of the wiring is important because the resistance in the wiring increases with the length. Kind of like when you walk ten miles and not five, you lose more energy on the long walk. So does electricity, and just like having good shoes can make that ten-mile hike feel less energy-draining then the five mile walk in bad shoes, using larger diameter wiring means the electricity loses less power.

Time to measure, and do it properly. Don`t think that if you have your battery at the back, and want your unit at the front, that the length of the wire will equal the length of you boat. Believe me, the wire will be a lot longer, so do the work and don`t guess. As an example, my boat is 15 feet, the cable from my rear battery to my console panel is 21 feet.

So now you know why you need to use a minimum size of wires, and you know the length and maximum draw. How can one find that minimum size? That calls for some calculation, and if you feel like testing your skills in math, you can do that manually. For those of us that are a bit more lazy, there are several on-line calculators that do this for us, and one of the better is from BlueSea: http://circuitwizard.bluesea.com/# That calculator is also available as an app on your smartphone, and that is what I`ll use as an example here.

Let us say you have bought a HDS 9 Live, and by looking in the installation manual you have found that this has a maximum draw of 2,9A that we will round up to 3A to keep things simple. (I like "simple".) You have measured in your boat and found that the total length of wiring will be 21 feet.

Open the app, choose "Calculate Wire Size":

|

| Calculate Wire Size |

|

| Don`t worry, the app will take you through all of these inputs. |

|

| 12V for the HDS Live in our example. |

|

| This we know from the installation manual. |

|

| We measured 21 feet, but since the electricity goes to the unit and back - double it. |

|

| For sensitive electronics, use 3%, for TMs and pumps etc. use 10%. |

|

| If the wiring is labeled with temperature, use that. If not input 60. |

|

| We typically have outboards, so that is a "no". |

|

| If you bundle this wire with other wires, choose the number of wires you bundle. If it will only be this one wire choose 1. |

|

| Enough for a full day of fishing. |

|

| Typically yes. |

|

| Almost done, press "Calculate" |

|

| Minimum wire size according to your input. |

|

| Same as above, only in metric numbers. |

That was it, not hard at all as long as one has done ones homework and know the draw and the total length of wiring. As mentioned you can use thicker wiring, that will give even less voltagedrop, and perhaps your next unit will be a 12, and not a 9 like in our example. If you oversize you can update electronics without running new wires every time you go bigger on your unit. Now off to the shop to get what you need, but before you run off take a few minutes to read some info on what fuse to use:

Fuse

In your manual, there will usually be something on what size fuse to use, but what the manual seldom tells you is that that size is the MINIMUM size to use. I`ll let you in on a little secret:

The fuse is MAINLY there to protect your wiring.

After reading that you probably think I`m crazy, so allow me to explain the reason for my bold statement.

A fuse will break or trip if the current (A) passing through it supersedes the fuse rating. Therefore, if you use a 5A fuse, and for some reason there is a 6A current going through it, the fuse breaks. That is the SOLE purpose of the fuse, it only protects against rising current. It does not protect against rising voltage, or a fool connecting the negative wire to the positive pole on the battery. Here comes the kicker - it is your unit that draws the current, the battery is not "pushing" out current that there is no need for. The only way to get a higher current flowing then your unit uses, is to short-circuit the negative and positive wire, and that has to happen AFTER the fuse in order for the fuse to break. If that short circuit happens between the fuse and the battery, the fuse will never know it and it won`t break, this is why a fuse should be placed as close to the battery as possible, NOT as close to your unit as possible.

What you need to protect is the wiring, so it does not overheat in case of a short circuit (or a user connecting equipment that draws a higher current then the wires can take without building up heat).

|

| Blade-type fuses work well in boats (photo; jula.no) |

A short can also happen within the unit itself, although that is very rare. If that happens the fuse will break, regardless of where you placed it between the unit and the battery.

Moral: As long as you have taken the time to correctly calculate the wiring needed (which you have), you can use the fuse recommended in the manual, or a larger fuse. Since you now have the BlueSea app, you can use that to see what size fuse you can use on the wiring you have choosen. In our example, the manual says minimum 4A, and the app says 4 to 10 so our calculation was correct and you can use any fuse between 4 and 10A.

Switch or not?

All things electrical on a boats should go through a switch, the ONLY exception is if you have an automatic pump in the bilge. If you wire your unit directly to the battery, with no switch, the connector will always have voltage in it, and that will cause issues at some point. Moist, humidity and plain old dirt will cause current to start creeping between the pins (or sockets) in the connector, this will slowly drain your battery and speed up corrosion in the connector, which again tends to lead to even more current and the problem escalates.

Keeping things tidy.

Using proper panels in your boat can help keep all the wiring tidy. I for one hate those loose fuses hanging off wires, and I hate loose wires. Keep it simple, use black wires for negative (ground) and red for positive (power), and look into using fuse-panels instead of having a zillion wires going from the back of the boat to the console or front. I highly recommend having at least one panel at the console, and in many cases one up front as well, both controlled by the main breaker in your boat. BlueSea fuse panels are great for such use.

|

| Crimping is more than good enough as long as it is done properly. |

|

| Ready for connecting units. |

Tinned or not tinned?

Tinned wires have a thin layer of tin between the copper and the plastic coating, the idea beeing to protect the copper from corrosion. This is normally not necessary on boats mainly used in freshwater, but it can be a good thing on boats used in saltwater. But if your connections on the wire are watertight (using shrink tubing with glue) and the plastic coating on the wire is not broken, there is no way for humidity to get into the wires, and thus no risk of corrosion either. You should regurlarly inspect your electrical system, especially looking for cracks, worn down plastic coating and bad connectors. Example of connector crimped and then sealed with shrink tubing with glue:

|

| Crimped and sealed with shrink tubing with glue. |

Dielectric grease?

Dielectric grease when used properly, yes. But there is a misunderstanding out there when it comes to dielectric grease and how it is to be used. Dielectric grease should NEVER be applied to a conductor in a low-voltage system, as it is not conductive, meaning it stops electricity going from A to B. Applying dielectric grease to the metal parts of any connector, decreases the functionality of that connector. It is however a good product for use on seals and many gaskets etc, just not on anything ment to deliver current/ power. There are many excellent spray can contact cleaners out there, designed to clean and leave the metallic surfaces (pins) conducting better, and that is what you should use from time to time (especially in saltwater) on the metal parts of any connector or socket. Personally I give all connectors and sockets that are regularly disconnected a dash of such spray every fall before leaving my boat in the boathouse over the winter.

I båt bør alt loddes og beskyttes med krympestrømpe med lim. Ledning må være fortinnet. Krymp og teip hører hjemme i skap innendørs. Har bitter erfaring på krymping av kabelsko etter plotter falt ut på åpent hav i tåke. Årsaken var ufortinnet ledning og krympede kabelsko.

SvarSlettHei Anonym.

SlettÅrsaken til problemet du opplevde er enten for dårlig utført arbeid til å begynne med, eller for dårlig ettersyn. Ufortinnet ledning er et problem dersom kobling eller ledningens plastbelegg har brudd slik at det kan komme til fuktighet. Er jobben gjort skikkelig, og ettersyn utføres jevnlig, så vil koblingene være vanntett og plastlaget på ledningen tett. Det er også verdt å nevne at tinn på ingen måte garanterer mot korrosjon, der det er mekanisk slitasje som gjør at plastbelegget slites bort, vil også tinn-laget slites av etterhvert og du får den samme korrosjonen, bare på et senere tidspunkt. Selv med tinn må man med andre ord etterse sitt elektriske anlegg, selv om jeg vil anbefale bruk av ledninger med tinn på båter som primært brukes i saltvann uansett. Ellers helt enig i at krympestrømpe med lim er å foretrekke, så jeg korrigerte artikkelen med litt informasjon om det nå.